Choose a series of electric motors:

Быстрый подбор электромотора

Высокотехнологичные электродвигатели и электрогенераторы от разработчика «Электромомент»

Наша продукция

Interesting facts:

Unlike asynchronous electric motors, synchronous electric machines have not yet created an international standard

Electromoment electric motors can be controlled by general industrial universal frequency converters designed to control synchronous electric machines

The synchronous drive consists of a control system with a frequency converter

The main drawback of DC motors is the presence of a collector, which reduces reliability and requires regular maintenance

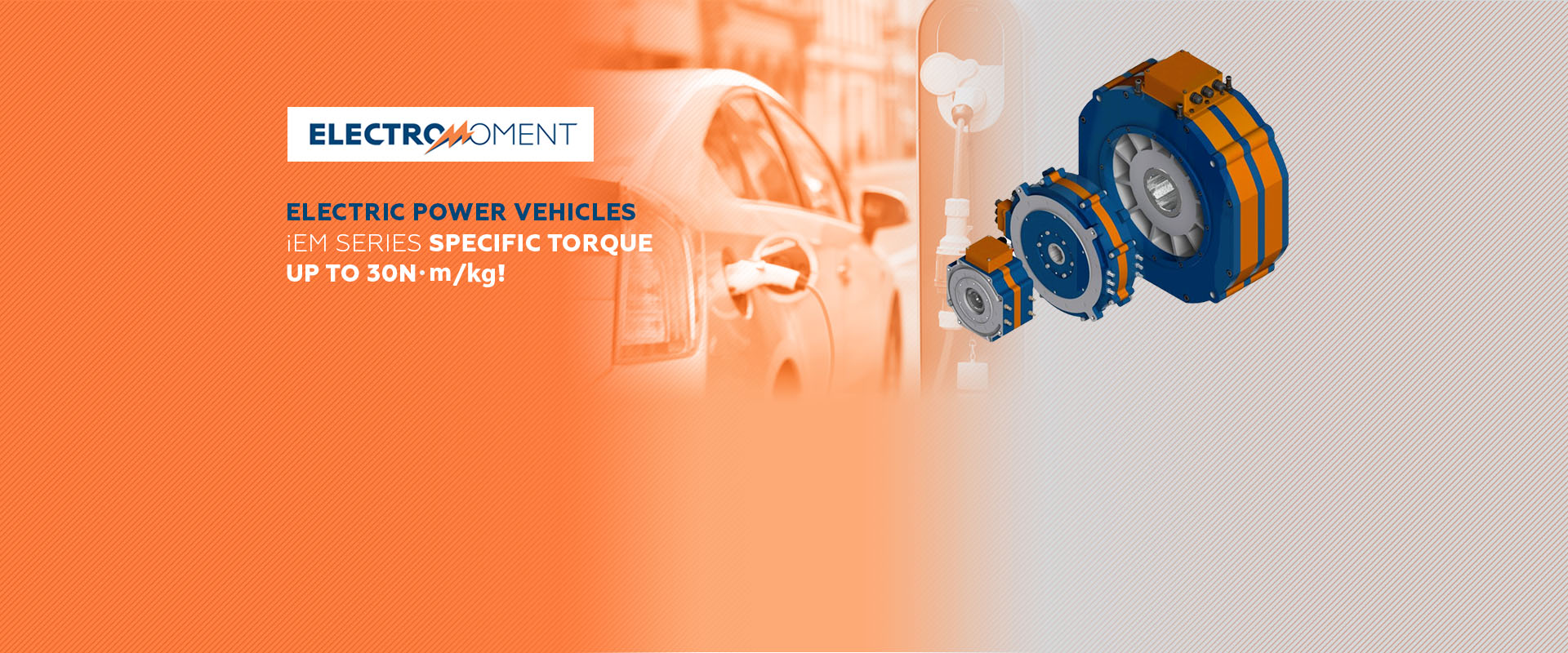

The higher the efficiency of the electric motor, the greater the opportunity to reduce its weight

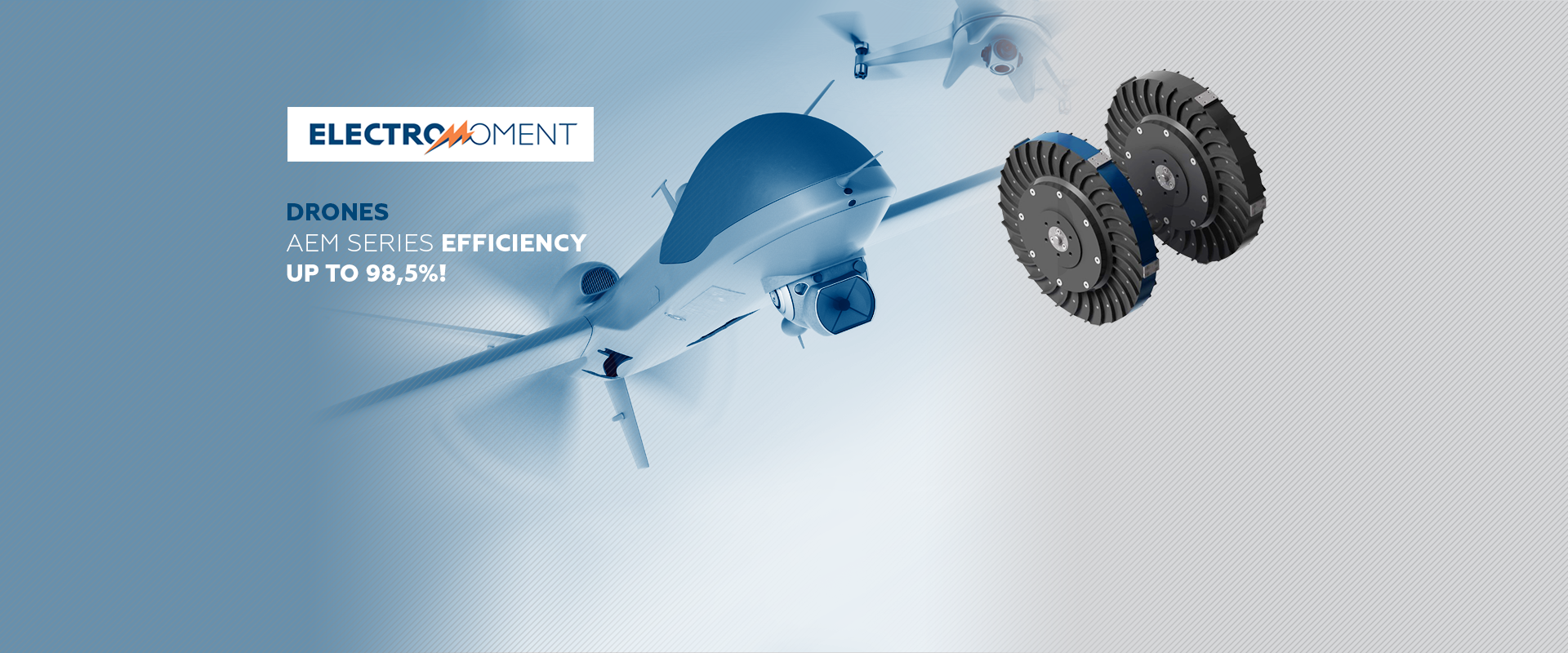

Modern agrodrones require special electric drives of the AEM series, which can be washed with a stream of water from a high-pressure washer

Electromoment electric motors are 4 times or more superior in torque to asynchronous motors of similar power!

To ensure high reliability of unmanned aircraft with a take-off weight of more than 30 kg, electric motors with a high degree of dust and moisture protection of the AEM series are required

The efficiency of Electromoment electric motors reaches 98.5% at nominal speeds

The power consumed by a synchronous electric motor, a linear function of speed

The design of Elektromoment electric motors uses modern composite materials and technologies

Electromoment electric motors are 4 times or more superior in torque to asynchronous motors of similar power!

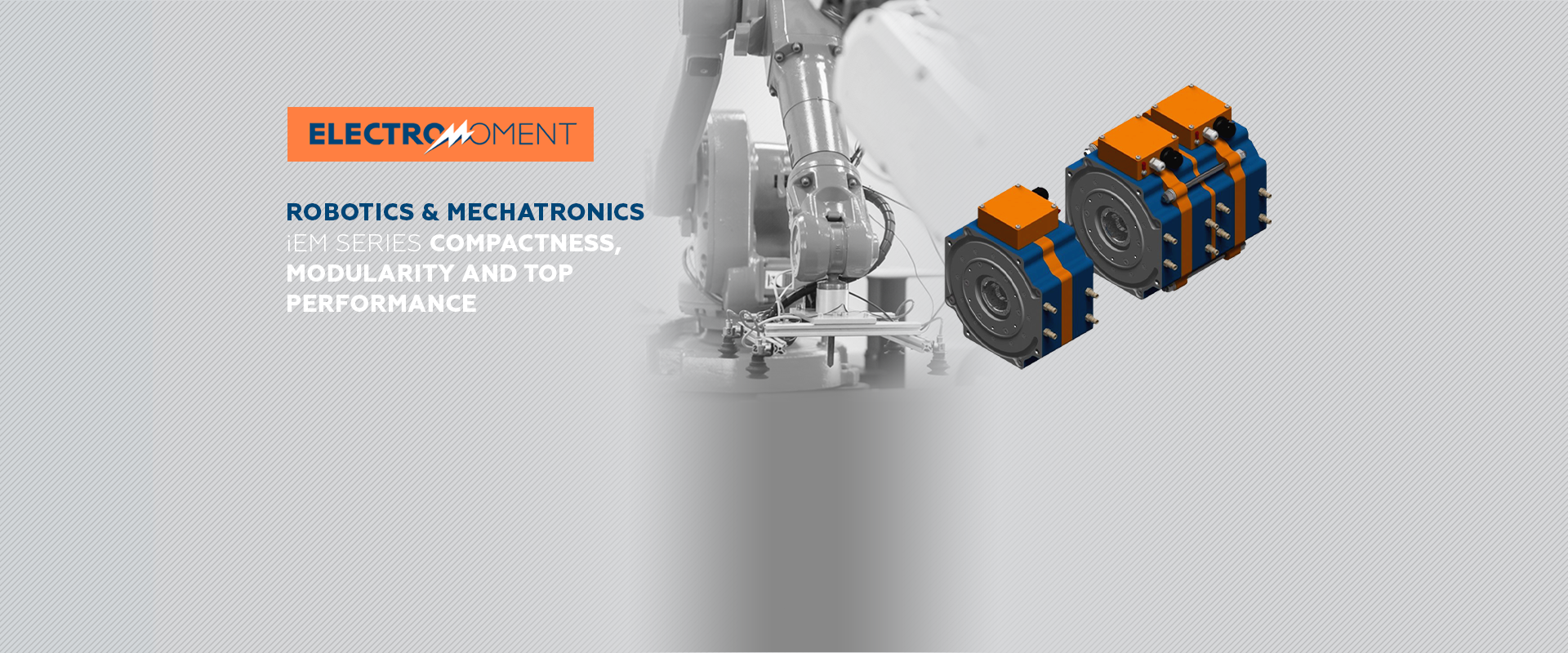

Unlike stepper motors, servo drives based on electric motors of the iEM and sEM series have much greater torque and positioning accuracy

Refusal of a mechanical gearbox in an electric drive significantly increases its efficiency, reliability, speed and rotation accuracy

Unlike synchronous servo drives, the torque of stepper motors is significantly reduced with increasing speed

Unlike asynchronous, synchronous electric motors have a constant torque in the entire operating range of the rotations

The absence of an iron armature in the innovative electric motors of the EM and AEM series provides them with the highest overload capacity!