Description

MAJOR MODIFICATIONS

Motor modules of the iEM-05w series can have the following modifications:

iEM-05w – standard version with forced liquid cooling and basic specifications. Priorities are low price and maximum import substitution while ensuring high specific characteristics.

iEM-05Lw are forced liquid-cooled modules with improved or maximum specific characteristics relative to standard iEM-05w modules. Priority – high or limiting specific characteristics in its class (specific torque or specific power). Limited import substitution for the Russian Federation, since imported materials and components are used to obtain the best specific characteristics. As a rule, they are produced in limited quantities due to the relatively higher cost of products of this modification.

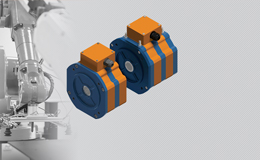

Modular scaling:

Electric drives based on iEM-05w / iEM-05Lw electric motors can be easily scaled by connecting two or three modules on a single insert shaft:

Package:

The basic package of iEM-05w includes:

- electric motor iEM-05w;

- Standard Flange Adapter (See Dimension Drawing on Documents Tab)

- IP65 terminal box for connecting power cables to the stator windings;

- quick fittings for cooling system hoses (4 pcs.);

- instruction for connection and operation;

- shipping container.

Additional equipment:

- standard shaft-insert (see the outline drawing with the index “RS” on the “Documents” tab);

- special shaft-insert, made according to the customer’s requirements;

- a set of parts for assembling an electric drive from several modules;

- special motor mounting flange adapter (according to customer’s drawings);

- external encoder with box and adapter for connecting to the main shaft;

- stator winding temperature sensors (1 or 2 pcs.);

- additional IP67 protection