Description

Asynchronous electric motor

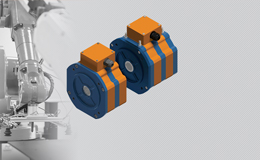

The EM-I-1500 Mk2 synchronous electric motor is an improved version of the EM-I-1500. Major improvements to Mk2 (Mark-2) are aimed at ease of integration, increased ease of installation and configuration of electric drives for many industries, from industrial automation to small electric transport. Unlike the EM-I-1500, the EM-I-1500 Mk2 has an oversized hollow shaft and a standard flange mount. These design improvements significantly expand the scope of application of the EM-I-1500 Mk2, making it easier to replace the classic general industrial electric drives “asynchronous electric motor with a gearbox” with a capacity of up to 6 kW for a synchronous electric drive EM-I-1500 Mk2 with a significant reduction in the reduction ratio or even complete rejection of the gearbox ( change to direct drive). This “upgrade” of the electric drive provides not only an impressive reduction in the mass and dimensions of the electric motor (more than 4 times!), But also an unusually high efficiency – up to 98.5%!

When the EM-I-1500 Mk2 is switched from motor to generator mode, a high-torque “electronic braking” mode is provided, and the efficiency of energy recovery at speeds close to nominal can reach 98.5%.

Reinforced composite stator CCSC-3 is the strongest part of the EM-I series electric motor

Despite its light weight, the EM-I-1500 Mk2 has high mechanical strength thanks to the patented CCSC-3 composite stator. and a reinforced hub with two SKF bearings. CCSC-3 technology provides almost complete absence of the so-called “magnetic sticking” (0.1 N·m), as well as maximum power factor with cos φ = 0.98!

The high-quality aluminum housing EM-I-1500 Mk2 is manufactured by injection molding and powder coating, which is resistant to shock and other mechanical influences.

An example of using EM-I-1500 Mk2 as part of a variable pump for viscous and abrasive liquids NRP 065

Reviews

There are no reviews yet.