Description

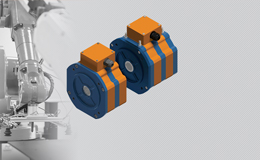

The synchronous electric motor EM-I-750 of axial type on permanent magnets has a high torque and is intended both for electric drives with a reduced reduction ratio, and for gearless electric drives (direct drive) of small electric vehicles, pumping equipment and ventilation systems.

Asynchronous electric motor

With 4-5 lighter weight and dimensions and very high efficiency in comparison with asynchronous electric motors, the EM-I-750 synchronous electric motor is primarily intended to replace classic general industrial asynchronous electric drives and electric drives of the “asynchronous electric motor with a gear” type with a power of up to 3 kW … This “upgrade” of the electric drive provides not only an impressive reduction in the mass-dimensions of the electric motor (more than 4 times!), But also reduces energy consumption, excluding heat losses in the gearbox, by 20-40%, depending on the operating mode of the electric drive!

The EM-I-750 electric motor has a built-in absolute encoder, which allows precise control of rotor rotation and power characteristics using modern universal frequency converters designed for multi-pole synchronous motors.

When the EM-I-750 is switched from motor to generator mode, a high-torque “electronic braking” mode is provided, and the efficiency of energy recovery at speeds close to nominal reaches 97%

Reinforced composite stator CCSC-3 is the strongest part of the EM-I series electric motor

Despite its light weight, the EM-I-750 has high mechanical strength thanks to the original CCSC-3 composite stator. The patented design of the CCSC-3 stator ensures almost complete absence of the so-called “magnetic sticking” (<0.1 N·m), as well as the maximum power factor with cos φ = 0.98!

The high quality aluminum housing EM-I-750 is manufactured by injection molding and powder coating, which is resistant to shock and other mechanical influences.

Reviews

There are no reviews yet.