Description

Unique characteristics:

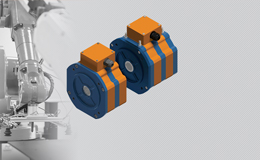

The AEM-08 2600 electric drive is designed to be used as a takeoff or main engine for medium-sized unmanned aerial systems (UAS) with a takeoff weight of up to 750kg of the eVTOL type (vertical takeoff and landing), using electric or hybrid power plant.

This electric drive was developed by the ELECTROMOMENT team primarily to solve the problem faced by the developers of medium UAS when trying to use traditional electric motors with a non-pressurized housing. It turned out that during vertical takeoffs and landings, especially from unprepared surfaces, propellers raise a large amount of dirt and dust, which are blown through the electromagnetic system of traditional electric motors and can disable them in a matter of UAS takeoffs and landings. The AEM-08 2600 rotating self-cooling enclosure is sealed to IP65 water and dust resistance. Such a high degree of protection is not provided by any other similar serial electric drive for air-cooled medium UAS! The sealed motor housing will also be appreciated by users of agricultural UASs designed to spray chemicals, which can now be flushed out with a pressure washer after each use.

One of the key advantages of AEM-08 electric motors is a phenomenally high efficiency, reaching 98.5% in the nominal operating mode! Such high efficiency is ensured by the patented CCSC, which greatly facilitates the task of removing excess heat from the stator windings. Since the stator CCSC, unlike traditional electric motors, does not have an iron armature, this provides electric motors of the AEM series with an impressive overload capacity of the electric drive in takeoff mode or emergency situation.

The high efficiency and effective self-cooling of the AEM-08 2600 allowed us to be the first in the UAS industry to integrate control system power switches directly into the motor cooling system! As a result of such integration, there is no need to use a separate heatsink for power switches, which significantly reduces the total weight of the electric drive, increases the final efficiency and manufacturability of the UAS design.

The combination of CCSC patented stator and MFF patented technologies gives the AEM series motors ultra-low rotor inertia , which allows the engine management system to change operating modes in hundredths of a second, including switching to emergency mode.

Major modifications:

Depending on the main direction of rotation of the propeller, electric motors of the AEM-08 2600 series have two modifications:

– AEM-08 2600CW (art. TM0301010) – for the main direction of rotation of the propeller clockwise;

– AEM-08 2600CCW (art. TM0301011) – for the main direction of rotation of the propeller counterclockwise.

Basic equipment of electric drives AEM-08 2600:

- electric motor AEM-08 2600CW or AEM-08 2600CCW;

- built-in power switches of the preamplifier control system;

- built-in encoder;

- built-in temperature sensor;

- connecting cables 2m;

- instruction for connection and operation;

- shipping container.

Additional equipment:

- additional temperature sensor;

- external block of the engine management system controller;

- propeller.