Description

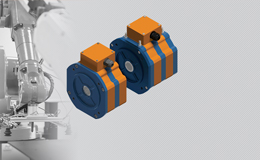

Standard basic models of servo motors sEM-07w and special versions sEM-07Lw are designed for use in high-precision power servo drives of CNC machines, machining centers, 3D printers and other industrial automation, robotics and mechatronics systems.

Thanks to their impressive torque, the sEM-07w series servo motors make it possible to partially or completely eliminate the need for a mechanical gearbox as part of the power servo drive!

sEM-07w power servomotors can be used in S1 continuous mode and S4-S10 continuous-periodic modes, complying with GOST IEC 60034-1-2014, with forced liquid cooling with performance depending on the operating mode of the servomotor. A high degree of dust and moisture protection and a wide operating temperature range make servomotors sEM-07w and sEM-07Lw indispensable in systems with severe operating conditions.

To control servomotors of versions sEM-07w and sEM-07Lw, the custom servo drives use universal or specialized 3- or 6-phase frequency converters designed for vector control of synchronous multi-pole servomotors with external feedback.

MAIN MODIFICATIONS

Servomotors of the sEM-07w series have the following modifications:

sEM-07w – standard version with forced liquid cooling and basic characteristics. The priorities are low price and maximum import substitution while ensuring high specific characteristics.

sEM-07Lw – custom liquid-cooled modifications with improved or maximum specific characteristics relative to standard modules sEM-07w. The priority is high or maximum specific power characteristics in its class. Limited import substitution for the Russian Federation, since imported materials and components are used to obtain better specific characteristics. As a rule, they are produced in limited quantities due to the relatively higher cost of products of this modification.

Content:

Included in the basic package is sEM-07w / sEM-07Lw includes:

- servomotor sEM-07w / sEM-07Lw with flange mounting and shaft with key;

- terminal box with cable entry and degree of protection IP65;

- quick-release fittings – 4 pcs.

- instructions for connection and operation;

- shipping container.

Additional equipment:

- shaft with shank according to the customer’s specifications;

- special flange adapter for motor mounting (according to customer drawings);

- external encoder with box and adapter for connection to the main shaft;

- frequency converter for servo drive.