Description

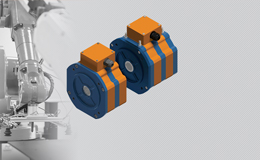

The iEM-Iw Mk2 modular electric motors are the second generation of the iEM-I series electric motors with improved power characteristics and ergonomics compared to the previous generation.

Electric drives based on the iEM-Iw Mk2 module with liquid cooling allow realizing a highly efficient and reliable direct drive system in modern systems of land and marine electric propulsion.

For example, in ground electric propulsion systems, electric drives based on the iEM-Iw Mk2 module make it possible to implement a highly efficient and reliable direct drive system for the axle shaft of each drive wheel. The choice of the number of iEM-Iw Mk2 modules in each electric drive from 1 to 3 pieces provides the ability to scale the drive power for driving wheels of both purely electric and hybrid vehicles (TC).

Modern synchronous drives of the iEM-I series open up for the developers of electric vehicles the prospect of creating modern electric vehicles with direct drive on two or more driving wheels and using an electronic differential instead of a mechanical one:

– the main disadvantages of the usual mechanical transmission of a car are excessive weight and complexity of the system, as well as limited reliability and resource

– the main disadvantages of the usual mechanical transmission of a car are excessive weight and complexity of the system, as well as limited reliability and resource

– when switching to efficient synchronous electric drives iEM-Iw, not only a radical simplification and reduction of the vehicle chassis weight is provided, but also the vehicle’s energy performance is significantly improved, including impressive acceleration dynamics, efficient braking energy recovery and new possibilities for vehicle motion control.

– when switching to efficient synchronous electric drives iEM-Iw, not only a radical simplification and reduction of the vehicle chassis weight is provided, but also the vehicle’s energy performance is significantly improved, including impressive acceleration dynamics, efficient braking energy recovery and new possibilities for vehicle motion control.

Key advantages of electric vehicles built on the basis of iEM-Iw Mk2 traction drives:

- high efficiency (> 94%) and the absence of overcurrents during acceleration ensure a 25-50% reduction in power consumption relative to classical gear and asynchronous electric drives;

- constant high torque throughout the entire speed range

- 3-4 times smaller dimensions and weight, which provides a significant reduction in the weight of the vehicle transmission (TC);

- high reliability due to the absence of a gearbox, simplified transmission and the possibility of modular duplication;

- efficient energy recovery in the vehicle electronic braking mode;

- low costs for periodic maintenance, long service intervals.

Reviews

There are no reviews yet.