Description

Electric drives based on the iEM-05w-625 electric motor module allow you to create power servo drives with the required positioning accuracy, which is set by an external encoder. The high torque of the iEM-05w-625 can either significantly reduce the reduction ratio of the power servo drive, or completely get rid of the mechanical gearbox, which significantly increases the reliability and efficiency of the electric drive. This opens up a wide field of application of the iEM-05w-625 electric motors in robotics, machine tool construction and other industrial automation systems.

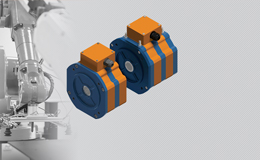

Increasing the number of iEM-05w-625 modules in the drive in the range from 1 to 3 pieces provides the possibility of proportional scaling of the drive torque and power.

– one-, two- and three-module electric drives iEM-05w-625

The graph of the dependence of the rated torque (Mnom) and power (Pnom) on the speed (n) for one, two and three iEM modules as part of the electric drive, where N is the rated speed

– intelligent drive of shut-off valves based on 2-module electric drive iEM-05w-625

Servo drives based on the iEM-05w-625 electric motor must be equipped with an external encoder with the required positioning accuracy and a frequency converter to control the electric motor. The selection of an encoder and a frequency converter for a servo drive is carried out by our engineers on the basis of the customer’s terms of reference (TOR).

Key advantages of power servo drives based on iEM-05w-625 high torque electric motors:

- constant high torque throughout the entire speed range;

- 2-4 times smaller dimensions and weight, which ensures high compactness and mobility of the system;

- high speed due to low inertia of the rotor;

- resistance to short-term overloads allows for a short-term development of a torque that is 2-3 times higher than the nominal

- high reliability due to reduction of steps or complete rejection of a mechanical gearbox, as well as the possibility of modular redundancy;

- absence of overcurrents during acceleration of the electric motor;

- ultra-low inertia of the iEM-05w-625 rotor ensures high speed of the servo drive;

- low costs for periodic maintenance, long service intervals;

- high efficiency (up to 94%) ensures a 15-25% reduction in power consumption compared to classic gear and asynchronous electric drives.

Reviews

There are no reviews yet.