With the development of modern industrial automation and robotics systems, designers are increasingly faced with the problem of choosing a suitable power servo drive. System requirements for torque, speed, positioning accuracy, compactness, reliability and energy efficiency of servo drives are steadily growing, but traditional electric drives are no longer able to provide the required technical characteristics in full. Rapidly aging conventional servo components include electric motor-gear systems and stepper motors.

With the development of modern industrial automation and robotics systems, designers are increasingly faced with the problem of choosing a suitable power servo drive. System requirements for torque, speed, positioning accuracy, compactness, reliability and energy efficiency of servo drives are steadily growing, but traditional electric drives are no longer able to provide the required technical characteristics in full. Rapidly aging conventional servo components include electric motor-gear systems and stepper motors.

Many are already familiar with the main disadvantages and limitations of the “electric motor with a gear” system as part of servo drives, especially in the version with asynchronous electric motors. Let us recall only the most unpleasant problem of a mechanical gearbox as part of a servo drive – it is a kinematic backlash due to the inevitable gaps between the gears.

Therefore, we will further focus on the problem of choosing the right type of electric motor for the gearless power servo drive.

Stepper motor.

Stepper motor.

Despite the unusual design and control method, stepper motors are usually classified as synchronous electric machines. At the same time, the high popularity and prevalence of stepper motors in some industries (for example, 3D printing) can be explained by such undeniable advantages as low price, simplicity of design and control, as well as acceptable angular accuracy for most applications.

However, the range of applicability of “shagoviks” is limited by a number of significant drawbacks:

- negligible torque: usually only a few N * m. The most powerful stepper motors barely reach 20 Nm.

- when the speed of rotation increases, the torque drops significantly;

- catastrophically low efficiency;

- lack of feedback leads to uncontrolled jumps or skipping steps during overload;

- mechanical limitation of the angular accuracy of the step;

- increased vibro-acoustic background and resonances.

Thus, “shagoviks” are well suited exclusively for low-power automation systems and mechatronics, in which energy saving is not important, but for the sake of a low price, you can put up with low torque and limited rotation speed. A stepper motor is not suitable as a precision, high-speed or powerful power servo drive.

Modern synchronous power servo drive.

2020 iEM-Iw Mk2, iEM-05w Mk2 and iEM-025w Mk2 Series Liquid Cooled Power Servo Drives

A modern power servo drive must meet the requirements of the 6th Technological Order and is characterized, first of all, by high specific torque, accuracy and speed. It must develop a torque from several tens to several thousand N * m, while having the minimum weight and dimensions.

A modern power servo drive must meet the requirements of the 6th Technological Order and is characterized, first of all, by high specific torque, accuracy and speed. It must develop a torque from several tens to several thousand N * m, while having the minimum weight and dimensions.

The specific torque of synchronous electric motors of the iEM series is in the range from 10.9 to 35 N * m / kg, which makes it possible to create on their basis compact power gearless servo drives developing a torque from hundreds to several thousand N * m with a given accuracy and speed!

To achieve the maximum specific power characteristics of the servo, air, liquid or combined forced cooling is used to remove excess heat from the motor housing.

In addition to the specialized synchronous electric motor iEM, the power servo drive must include: a frequency converter with a control system and an encoder that provides the required angular accuracy.

IEM-Iw Mk2 Series Liquid Cooled Flange Mounted Power Servo Drive (Front View) delivering up to 1,000 Nm of torque

IEM-Iw Mk2 Series Liquid Cooled Flange Mounted Power Servo Drive (Rear View) delivering up to 1,000 Nm of torque

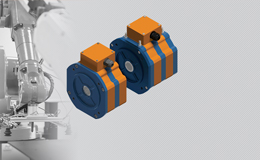

The modular design of the air-cooled or liquid-cooled iEM motors not only allows easy scalability of servo torque and power, but also provides additional reliability through modular redundancy.

Updated iEM-I Mk2 Series 2-Module Air Cooled Power Servo with Mounting Bracket (Front View)

Updated iEM-I Mk2 Series 2-Module Air Cooled Power Servo with Mounting Bracket (Rear View)

A temporary disadvantage of power servos based on iEM modules is the higher price compared to traditional solutions. However, due to the high efficiency, relatively low installation and maintenance costs, the cost of ownership is significantly lower and will pay off the higher acquisition cost in a matter of months.

The technological effectiveness of the iEM composite structure allows